Boxcoolers

Using Blokland boxcoolers in the design of efficient cooling system, has been done during many years for different types and sizes of ime vessels and installations. Installed in the primary cooling circuit, boxcoolers obviate the need for raw water pumps, filters and piping systems and prevent the corrosion issues related to them. Over the years different types of workboats, cargo vessels, fishing boats, ferries and dredgers have been using these coolers for main engines, generators and auxiliary systems. Nowadays boxcoolers are not only used in modern fuel-saving and green fuel propulsion solutions, but are also part of the fuel saving measures.

360 view

Boxcooler applications

Boxcoolers can operate in fresh- and brackish water, seawater and in special environments. A boxcooler will be supplied as a package, complete with a steel or aluminium welding frame, avoiding the need for drilling and tapping. Boxcoolers can be supplied in many sizes and shapes, with cooling surfaces from just over 0,5 m² to more than 150 m². The depth of a boxcooler can be adjusted for shallow draft applications, while the shape can be designed to follow the curvature of a ships hull.

Boxcoolers with certificate

When required, the boxcoolers will be supplied with a test- and witness certificate from a classification societies of choice. Blokland has extensive experience with many class societies, such as: ABS, BV, DNV-GL, KR, LRS,NKK, RINA, RMRS, RRR etc.

Boxcoolers and Marine Growth

Boxcoolers are in direct contact with the water the ship sails in. The biodiversity in coastal regions and estuarine conditions can be responsible for the growth of biological fouling, also on the boxcoolers. To prevent this marine growth from obstructing the free flow of water around the coolers, so-called marine growth prevention systems can be installed. An ICAF (Impressed Current Antifouling) system provides an unattractive environment for marine fouling. Unfortunately this system generates copper ions. Blokland has, recently, invested heavily in the development of an advanced ultrasonic system, which is capable of preventing a substantial amount of marine growth to settle on the coolers. Under specific conditions, especially where in coastal area’s the seabottom is disturbed by dredging operations, this ultrasound technology, might not be enough to keep boxcoolers sufficiently free from fouling. Especially for these conditions the GreenSonic hybrid system was developed, combining both technologies, with the advantage of reducing the amount of copper being dissolved, substantially.

360 view

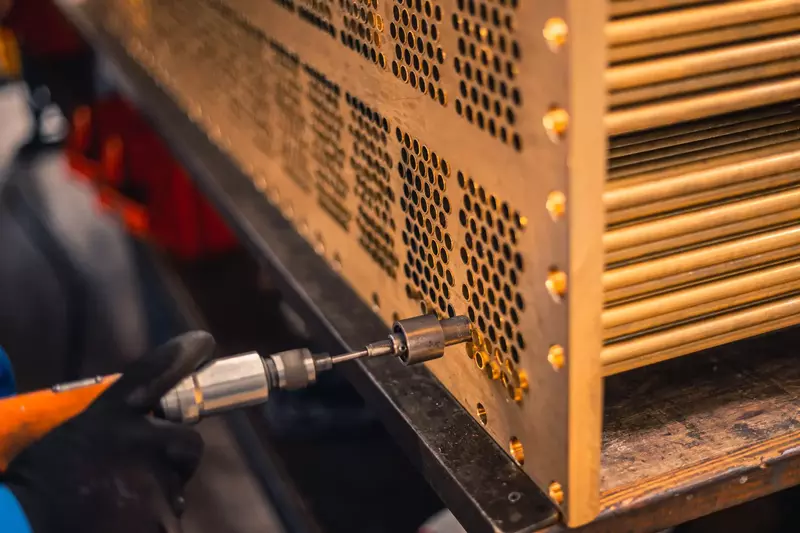

Boxcooler installation

Boxcoolers can be installed in longitudinal or transversal direction inside the seachest. To optimize natural circulation and heat-transfer boxcoolers should be installed with a minimum of 150 mm of free space between the tubes and the internals of the seachest. Boxcoolers can be removed and re-installed, when the topplate of the seachest is above the waterline, when the vessel is afloat.

Please contact our sales department.

Also part of Blokland Group:

Cooling solutions for marine and industry

Visit website

High-tech propulsion systems

Visit website

Precision seals and propulsion components.

Visit website

Next level anti-fouling solutions.

Visit website

Electrically driven thrusters for workboats, canal cruisers, hydrofoils, and inland vessels.

Visit website

Reliable electric propulsion for builders of boats, tenders, and commercial shipping.

Visit website