Our story with over 50 years of experience

Blokland Non Ferro develops, produces and supplies heat exchangers, propulsion systems and related technical products for pleasure crafts, commercial shipping and industrial applications for many years.

Our history

1962

Founding of Blokland Non Ferro

Our founder Jan Blokland started building yachts together with his brother Wim Blokland in 1962. The brothers were innovative and started to produce and use small heat exchangers and other products in their yachts. As a result, other companies started to inquire and order these small heat exchangers as well as other products.

1969

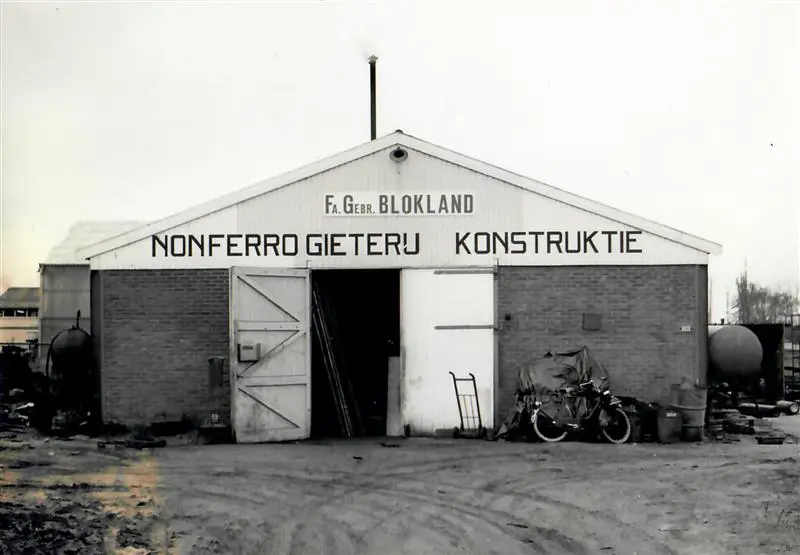

Acquiring Non Ferro Gieterij

The brothers Blokland acquired the Non Ferro Gieterij (foundry) in 1969. Blokland started to develop and manufacture marinization parts for diesel engines. The production and development of shell & tube heat exchangers still continued. After a few months, the brothers Blokland decided in favour of splitting the company and Jan Blokland continued with Blokland Non Ferro.

1970's

First expansion

In the mid of the 1970’s it was time for the first expansion. The expansion was necessary for the growth of both work and personnel.

1980’s

Design & Production

At the beginning of the 1980’s the design and production of the box coolers as well as propeller shaft systems started. Both products would turnout into a great success. The picture shows Jan Blokland machining parts for a propeller shaft system at younger age.

1983

Expansion

Another expansion of the Blokland premises was realized in 1983.

1993

Renewing the building halls

One of the earlier built building halls has been renewed in 1993. The picture shows Jan Blokland together with his daughter Corine.

1996

Jan Blokland

Our founder Jan Blokland passed away in 1996 at young age. Subsequently, Jan’s daughter Corine took over the business from her father.

2007

Renew building hall

The building hall, which was build in 1983, has been renewed in 2007. The picture shows Corine with one of her children.

2014

Acquired Amartech

Amartech was acquired in 2014, causing the capabilities of the propulsion department of Blokland Non Ferro to increase significantly.

2017

Two new building halls

Two new building halls were realized in 2017. The new production halls were necessary for the increased activities of the departments propulsion and repair/cleaning of coolers.

2018

Exalto propulsion

The machine shop, personnel and know-how of Exalto propulsion were acquired by Blokland Non Ferro in 2018. Accordingly, the entire machine shop of Exalto was transferred to the workshop in Sliedrecht.

2019

VMtech

The activities of VMtech (Aart Vermeij) were taken over by Blokland Non Ferro in 2019. VMtech was mainly specialised in the design and supply of Rubber Bearings and Lost Wax Metal Castings.

2021

Product groups bearings

In 2021 Blokland Non Ferro acquired the product groups bearings, cap nuts and deck caps of Bonsink Aquaservice. The products became part of Blokland's propulsion program.

2021

Third generation family owned company

In 2021 the two oldest sons of Peter and Corine started their professional careers at Blokland Non Ferro.

Third generation of Blokland

2021

Opening sales office Beugen

In November 2021, we have opened another sales office in The Netherlands. The sales office (office South) is located in Beugen.

2023

Renovation of a part of our building

In 2023, we unveiled the renovated part of our building in Sliedrecht, which is now in line with the previous new construction and has undergone a considerable expansion of our area.

2023

Solar panels

In 2023 we've installed more than 700 solar panels on our premises. These solar panels will not only help us become more environmentally responsible but also pave the way for a brighter and greener tomorrow.

Dutch craftsmanship

We pride ourselves in integrating Dutch craftsmanship with sophisticated know-how and the latest technologies. To our craftsmen, perfection is the highest priority. Blokland operates with a team of motivated and enthusiastic individuals who do not accept anything less than perfection. We encourage our employees to cooperate with each other and take responsibility.

Innovation

Innovation is part of our DNA. We are well-know worldwide for our outstanding products and game-changing innovations. Still, we don’t take anything for granted. We continuously invest in R&D and innovation, and forge ahead to deliver the best equipment and services for marine and industry applications.

Meet our team

The Blokland team of more than fifty craftsmen, engineers and sales engineers is at your service. We love to get in touch with you to realize the best solution for your specific application. We keep your business moving.